Zamak die-casting

Zamak ingots are melted in a crucible and then cast in a steel mould, where they solidify into the desired shape.

Die-casting . Injection moulding

MIM . Impact moulding . Hot-pressing

CNC . 3D Printing . Polyjet Printing

Turning . Precision casting . Cleaning and polishing

Injection moulding

Since most plastic material is meltable, casting processes involve the melting of nylon or ABS chips in the machine, followed by injection into a steel mould.

MIM

Metal Injection Moulding is a complex stainless steel moulding process used to obtain accessories of various sizes and complex shapes. It consists of three phases: moulding, debinding and sintering.

Impact moulding

One of the most widely used processes for rolled strip moulding. A pitch mould is used to sheer off the material which is then deformed to obtain the finished product.

Hot-pressing

Brass billets are heated to softening point, pressed and moulded by an equaliser. The process concludes with the cutting of excess burrs.

CNC

Using specific milling machines, brass, steel and aluminium can be modelled mechanically.

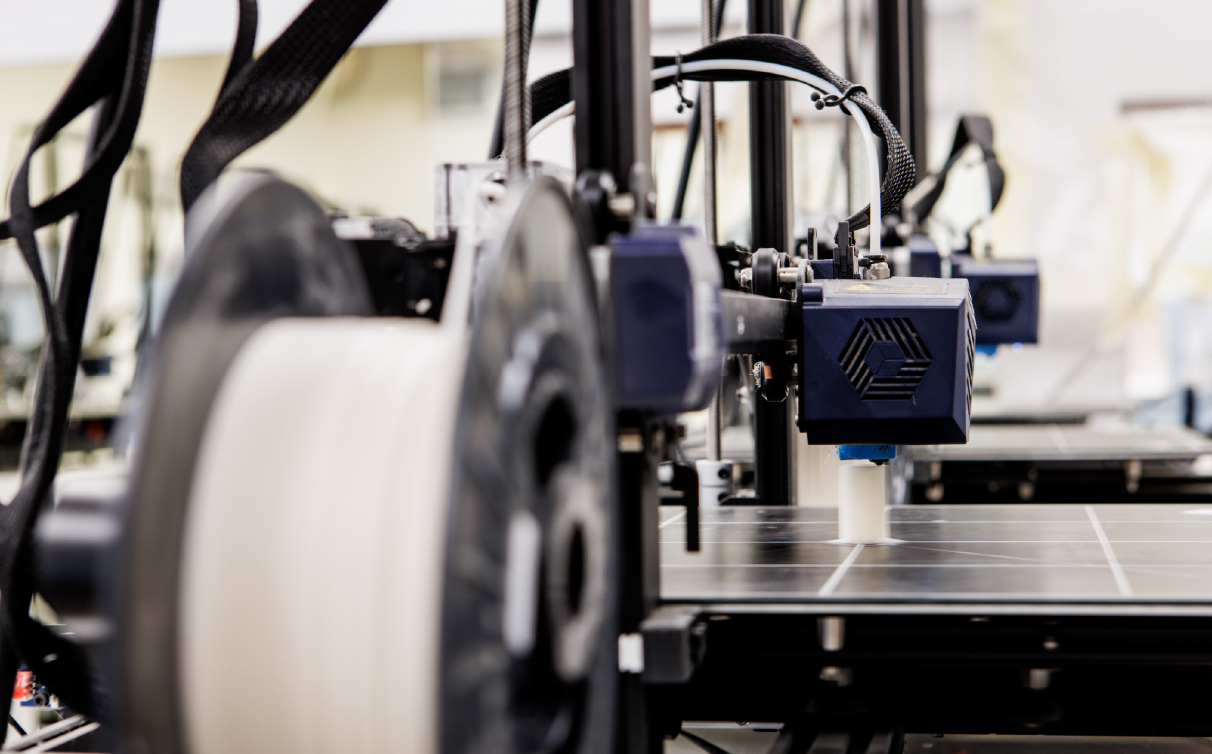

3D Printing

3D printing is an additive technique, which is used with software to create a three-dimensional object, layer after layer, with resins in the form of filaments and powders.

Polyjet Printing

The most advanced technique out of all 3D printing processes. It stands apart from the rest as it involves colour printing. Layers of liquid photopolymers solidify, bringing to life precise three-dimensional models.

Turning

A mechanical operation involving the machining of material in the form of a bar through the removal of shavings. This technique is suitable for giving particularly recessed shapes to steel, brass and aluminium objects.

Precision casting

It is the technique of choice when working with brass for obtaining undercut shapes, which would not be possible with printing. It is often used as a prototyping technique.

Cleaning and polishing

Cleaning and polishing are mechanical operations used to remove sediments and burrs from the surface of the accessory. They involve several operations: roughing, chamfering, grinding, brushing and polishing.